How to read welding inspections gauges

Welding inspections gauges are available for checking alignment, checking dimensions before welding, verifying weld dimensions, and checking porosity of welds.

Some gauges are multipurpose or single purpose.

instructions for WG-1 | WG-2 | WG-3 | WG-4 | WG-5 | WG-6

WG-1 HI-LO ® Welding Gage measures internal alignment of pipe after fit-up/ alignment. This cuts radiographic rejects. It measures internal misalignment of pipe before and after tacking. Measurements read in inch on one side and metric on the opposite side. The gauge measures internal mismatch of pipe wall, scribe lines, weld fillet and crown height. It satisfies fit-up codes ASME, ANSI, API & Military.

WG-2 Economy Single Purpose HI-LO ® Welding Gage is designed for internal alignment and determining rootweld spacing.

Internal HI-LO ® gage. Four quick steps check internal

alignment

You can check the internal alignment of your fit-up quickly with

the WG-2 HI-LO Gage.

1. unlock the retaining screws. Press the gage legs beyond the

barrel.

2. insert the legs ( wires ) into the root gap space of the two

pieces of pipe to be fitted. Turn the gage 90 º, being careful

to apply a constant back pressure to the barrel.

3. Hold the gage as square as possible with the fitting to obtain

an accurate reading. Lock the retaining screw, Reverse the 90º

turn and remove the gage. You've now ready to read the increment

opposite the red line.

4. When the red line aligns with the 1/32 increment you have a

good internal alignment and fit-up. Misalignment can be determined

from the zero line by increment markings of 1/16 inch.

Rootweld spacing gage. Easy operation determines rootweld spacing.

1. Unlock the retaining screw and insert the gage interior alignment stops between the two pieces of pipe to be fitted.

2. Insert the leg with the long taper into the root gap until it makes contact with both sides of the gap.

Relock the retaining screw, remove the gage and read it.

3. The scale is calibrated in fractional dimensions from 1/32 to 3/16 inch in 1/16 inch increment markings. The readout you receive represents the amount of the rootweld gap.

WG-3 adjustable fillet weld gauge with unequal leg measurement

feature.

This gauge measures any fillet weld from 1/8" to 1"

to 1/32" accuracy with just one simple to use gauge.

The WG-3 adjustable fillet weld gauge used an offset arm which

slides at a 45º angle to make fillet weld length measurement.

Simply adjust the arm until it touches the toe of the vertical

leg. The gage is calibrated to 32nds. Four screws hold the offset

arm in position for future adjustments.

This gauge also measures weld throat thickness to 1/16" of

an inch by adjusting a pointer in position for future reference.

If the weld is concave, more filler material can be added to build

the weld throat up to standard. The WG-3 adjustable fillet weld

gauge is made of durable, rust resistant stainless steel. Its

2-1/4 x 3" slim design weighs only 1-1/2 Oz. It fits easily

into a shirt pocket. Because there is just one gage need to make

all measurements, the chance of losing essential fillet weld gage

blades is eliminated. Fumbling through seven different gages blades

is also eliminated.

WG-3 adjustable fillet weld gauge measures both leg lengths and

weld throat fillet weld thickness.

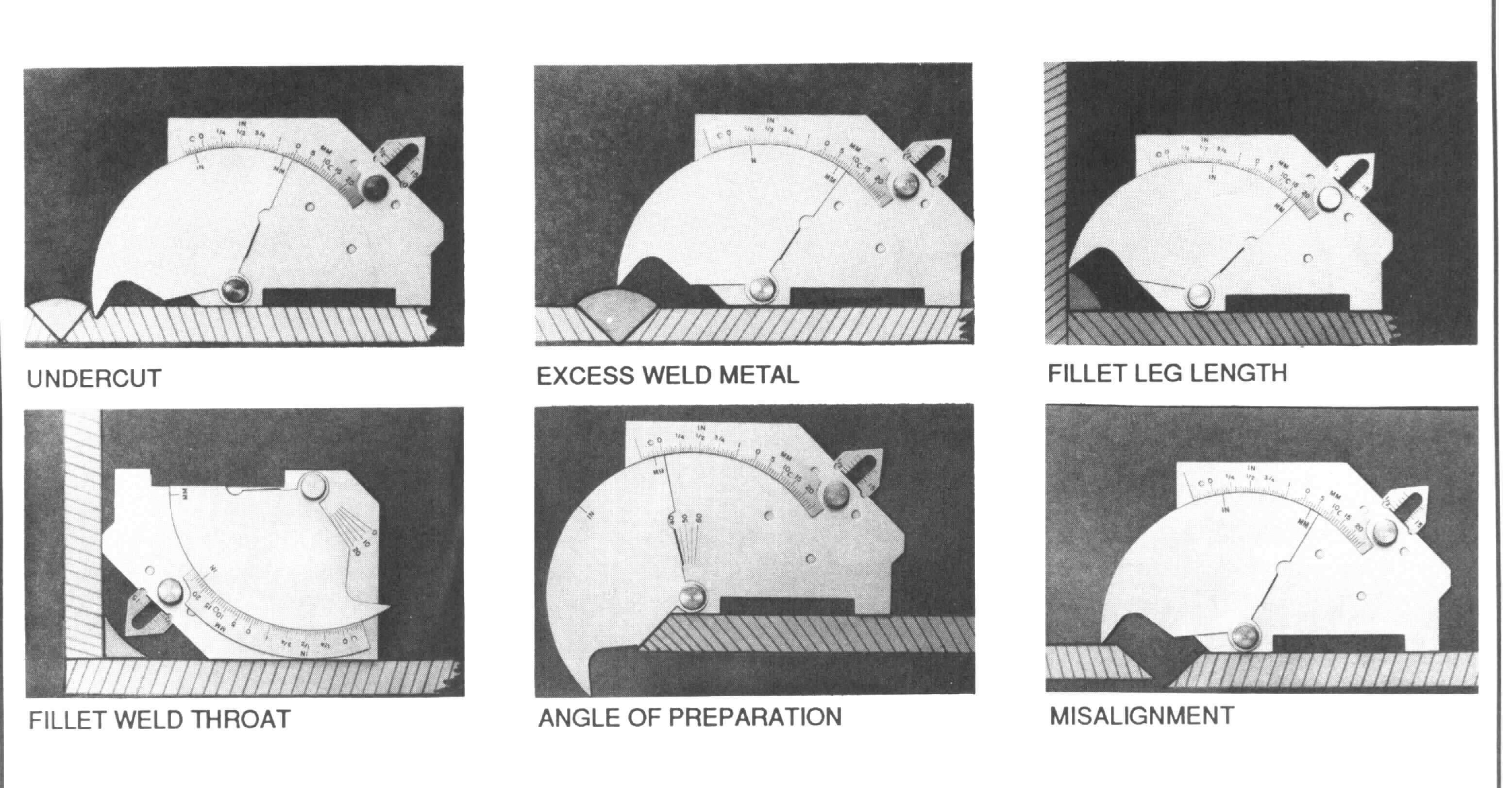

WG-4 Weld Gauge or Bridge Cam Gauge is a unique, versatile instrument for the inspection of welded surfaces and joints.

It measures angle of preparation, 0 to 60 º, excess weld metal ( capping size), depth of undercut, depth of pitting, fillet weld throat size, fillet leg length, misalignment ( high-low), and linear measurements up to 60mm or 2 inches.

It measures in both inch or millimeters.

It is easy to use. It comprising of one rotating dial and one sliding pointer. Move the dial or pointer until it makes the appropriate contact and then read the result.

WG-5 V-WAC ™ Gage quickly determine if fillet welds meet

NRC Visual Weld Acceptance Criteria for structural weldments.

It easily and quickly checks the four essential measurements required

for compliance with NRC Visual Weld Acceptance Criteria. It checks

undercut depth, porosity comparison, amount of porosity per linear

inch and crown height.

The undercut depth or crown height scale can be read to 1/32 inch.

Porosity comparision of 1/8" and 1/16 inch. Linear gage in

1/16 inch increments. The gage is easy to set and a locking screw

holds it in position for later reference. All four required measurements

are made with a single gage.

WG-6 A.W.S. Type Gauge. Automatic weld size weld gage for accurate

calibrations of butt and fillet type welds. With the WG-6 A.W.S

Type Gauge it is possible to meet specifications of butt and fillet

type welds. The following diagrams illustrate the ease with which

welders and inspectors may accurately check sizes of convex or

concave fillets as well as butt weld reinforcements.

The convexity and concavity sizes have automatically been determined

in accordance with American Welding Society D1.1 Paragraph 3.6.

The gauge is built of stainless steel with dimensional readings

chemically etched and filled for easier reading.