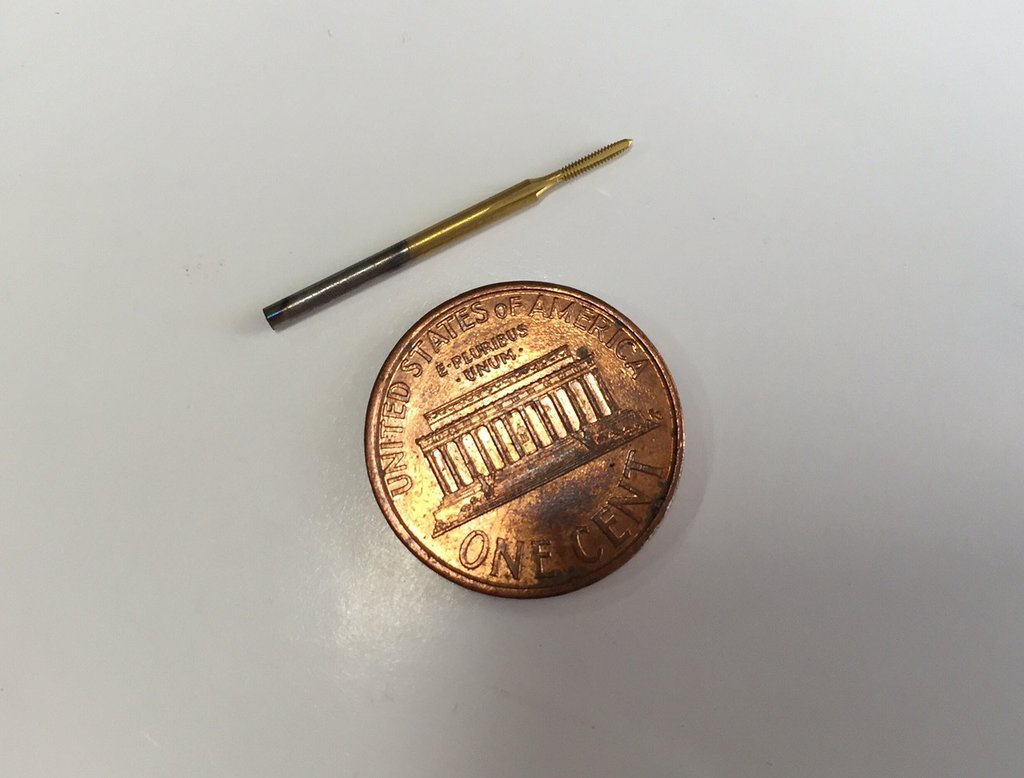

Micro Miniature Taps

UNM thread series and Unified and American Thread Series

These series have fourteen miniature metric thread sizes that are systematically distributed from .30mm to 1.40mm in diameter and supplements the Unified and American Thread Series that begins at .060 inch diameter.

The diameter-pitch combinations provide for maximum strength against stripping and for excellent manufacturability and interchangeability.

The Unified National Miniature Thread Series (miniature metric thread) was accepted as a new thread series in 1958 and was intended for general-purpose use in instruments, miniature mechanisms, and for jewelry and watches. The use of this series is recommended for all new products in place of the old standard miniature and the many improvised thread sizes still in existence. We will continue to supply the ongoing demand for the old standard miniature screw threads.

The UNM thread series

has fourteen miniature metric thread sizes that are systematically

distributed from .30mm to 1.40mm in diameter and supplements the

Unified and American Thread Series that begins at .060 inch diameter.

The diameter-pitch combinations provide for maximum strength against

stripping and for excellent manufacturability and interchangeability.

Technical data contained

in this site is taken from Fed-Std-H28/5 and ASME B1.10M-1997.

Unified National Miniature Thread Series

|

Designation |

Major Dia |

Pitch mm |

Approximate Threads per inch |

|

.30 UNM |

.30mm (.0118) |

0.080 |

318 |

|

.35 UNM |

.35mm (.0138) |

0.090 |

282 |

|

.40 UNM |

.40mm (.0157) |

0.100 |

254 |

|

.45 UNM |

.45mm (.0177) |

0.100 |

254 |

|

.50 UNM |

.50mm (.0197) |

0.125 |

203 |

|

.55 UNM |

.55mm (.0217) |

0.125 |

203 |

|

.60 UNM |

.60mm (.0236) |

0.150 |

169 |

|

.70 UNM |

.70mm (.0276) |

0.175 |

145 |

|

.80 UNM |

.80mm (.0315) |

0.200 |

127 |

|

.90 UNM |

.90mm (.0354) |

0.225 |

113 |

|

1.00 UNM |

1.00mm (.0394) |

0.250 |

102 |

|

1.10 UNM |

1.10mm (.0433) |

0.250 |

102 |

|

1.20 UNM |

1.20mm (.0472) |

0.250 |

102 |

|

1.40 UNM |

1.40mm (.0551) |

0.300 |

85 |

Common Old Standard Miniature Instrument Threads

|

Designation |

Major Dia |

Threads per inch |

|

00-90 |

0.047 |

90 |

|

00-96 |

0.047 |

96 |

|

00-112 |

0.047 |

112 |

|

000-120 |

0.034 |

120 |

|

0000-160 |

0.021 |

160 |

|

CUT THREADS |

FORMED |

||||||

|

THREAD |

UP TO 2/3 MAJ DIA * | 2/3 TO 1 1/2 MAJ DIA * | 1 1/2 TO 3 MAJ DIA * | ||||

|

Min |

Max |

Min |

Max |

Min |

Max |

||

| 1.40 UNM |

0.0439 |

0.0455 |

0.0450 |

0.0471 |

0.0460 |

0.0481 |

0.0498 |

| 1.20 UNM |

0.0379 |

0.0393 |

0.0388 |

0.0406 |

0.0397 |

0.0415 |

0.0438 |

| 1.10 UNM |

0.0340 |

0.0354 |

0.0349 |

0.0367 |

0.0358 |

0.0376 |

0.0397 |

| 1.00 UNM |

0.0300 |

0.0314 |

0.0309 |

0.0327 |

0.0319 |

0.0337 |

0.0358 |

| 0.90 UNM |

0.0270 |

0.0283 |

0.0279 |

0.0295 |

0.0287 |

0.0304 |

0.0318 |

| 0.80 UNM |

0.0241 |

0.0252 |

0.0248 |

0.0263 |

0.0256 |

0.0270 |

0.0283 |

| 0.70 UNM |

0.0211 |

0.0221 |

0.0217 |

0.0231 |

0.0224 |

0.0237 |

0.0248 |

| 0.60 UNM |

0.0181 |

0.0190 |

0.0187 |

0.0198 |

0.0193 |

0.0204 |

0.0212 |

| 0.55 UNM |

0.0170 |

0.0178 |

0.0176 |

0.0186 |

0.0181 |

0.0191 |

0.0195 |

| 0.50 UNM |

0.0150 |

0.0158 |

0.0156 |

0.0166 |

0.0161 |

0.0171 |

|

| 0.45 UNM |

0.0141 |

0.0147 |

0.0145 |

0.0154 |

0.0149 |

0.0158 |

|

| 0.40 UNM |

0.0121 |

0.0127 |

0.0125 |

0.0134 |

0.0130 |

0.0138 |

|

| 0.35 UNM |

0.0105 |

0.0111 |

0.0109 |

0.0117 |

0.0113 |

0.0121 |

|

| 0.30 UNM |

0.0089 |

0.0095 |

0.0093 |

0.0100 |

0.0096 |

0.0104 |

|

| 00-90 |

0.0358 |

0.0380 |

0.0374 |

0.0395 |

0.0385 |

0.0405 |

0.0426 |

| 00-96 |

0.0371 |

0.0385 |

0.0381 |

0.0400 |

0.0390 |

0.0409 |

0.0429 |

| 00-112 |

0.0386 |

0.0398 |

0.0394 |

0.0410 |

0.0402 |

0.0419 |

0.0435 |

| 000-120 |

0.0261 |

0.0273 |

0.0270 |

0.0280 |

0.0277 |

0.0293 |

0.0306 |

| 0000-160 |

0.0151 |

0.0160 |

0.0157 |

0.0170 |

0.0164 |

0.0176 |

0.0184 |

Because these small taps are fragile, it is recommended that 75% thread be adopted only for soft materials and short threaded holes. As the length of the hole increases, the percentage of thread should be decreased. The depth of the hole to be threaded (*) as a function of the major diameter is provided in three groups and each group has a minimum and maximum for tap drill size. The minimum diameter should be used for soft and ductile materials and the maximum drill diameter for harder and more difficult materials. In many cases the hole diameter does not correspond to a numbered drill, so the closest millimeter drill should be selected.

The tap drill sizes shown for form taps are only a recommendation as a starting point. Depending on the material being tapped and the depth of the tapped hole, the hole size may have to be slightly increased or decreased to obtain good thread form and good tap life.